Web Converting Systems

Pyradia Web Converting Systems manufactures custom engineered roll-to-roll process equipment from complete adhesive web coating & laminating lines to single winding, drying, calendering and web handling components. For over 25 years, our engineering team has been designing machinery to answer the most challenging process requirements from the Automotive, Pressure Sensitive Adhesive, Film, Flexible Packaging, Medical, Defence, Construction and Electronics industries.

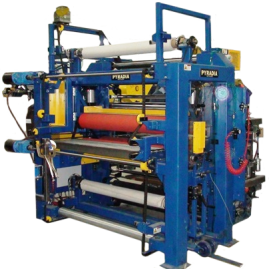

Adhesive Coating & Laminating Lines

Pyradia has been a renowned manufacturer of web converting machinery since the early 90’s. We design and manufacture complete web coating and converting lines tailored to our customer’s specific needs. Pyradia’s oven division has been an industry leader in convection, infrared and combination drying solutions for over 45 years, providing complete coating and drying process knowhow. Pyradia adhesive coating and laminating web lines are tailored for your specific application, such as pressure and thermal sensitive adhesives, release liners, electronics, batteries, filtration, medical & pharmaceutical, tapes, barrier films, packaging and more, and can be designed for various substrates, including paper coating, film coating, foam coating, foil coating, nonwovens coating, rubber coating and membrane coating. Our experienced engineering team will guide you through selecting the ideal coating method, whether your process requires Direct Gravure coating, Reverse Gravure coating, Offset Gravure coating, Knife-Over-Roll (KOR) coating, Reverse Roll coating, Saturation coating, Mayer Rod coating, or Slot Die coating.

Pyradia’s customer-centric design approach provides innovative solutions, flexible modular designs, and machines built according to the highest quality standards to optimize your roll-to-roll or continuous high-speed operation. Visualize our latest installations and testimonial videos from JDC Solutions below.

JDC Solutions Client Testimonial - Youtube Video

Get Quote

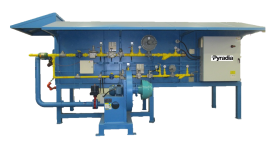

Silicone Coating Lines

Pyradia manufactures a wide range of silicone coating lines, from thick filled silicone products to thin silicone release liners, whether your application requires solventless, solvent based or water emulsion silicone coatings, for producing siliconized paper and films. We offer silicone coating solutions that are tailored for your specific application, with Knife-Over-Roll (KOR) coater for thick layers, direct or offset gravure for thin coat weight and multi-roll offset split-film roll coater for extra low coat weight, both for single and dual-sided processes.

Pyradia manufactures a complete range of convection, infrared and combination dryers, including flotation dryers for dual sided coating applications.

Our experienced engineering team will guide you through selecting the ideal coating method and dryer configuration for your specific product. We have experience with a wide range of products such as: pressure-sensitive release liners, graphic arts and labels, healthcare, automotive, electronics, foams and tapes.

Pyradia’s customer-centric design approach provides innovative solutions, flexible modular designs, and machines built according to the highest quality standards to optimize your production, whether you require roll-to-roll or continuous high-speed operation. Visualize our latest silicone coating installation below.

Pyradia KOR Coating Web Converting Line - Youtube Video

Get Quote

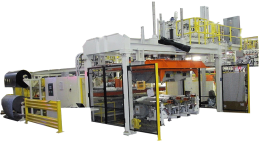

Custom Drying Solutions

Pyradia’s oven division has been an industry leader in convection, infrared and combination solutions for over 45 years, providing in-depth knowledge required for manufacturing heat treatment lines for various process and substrates. Pyradia expertise covers a wide range of technical textiles applications, such as: nonwoven heat treatment line, composite curing, prepreg polymer resin impregnation lines, whether equipped with single position or fully automatic turret unwinds and winders, with a wide variety of heat source, such as: electric, steam, direct fired natural gas or liquid propane, indirect fired natural gas, or hot oil.

Our experienced engineering team will guide you through the selection and design of your new Pyradia turnkey oven heat treating line, drying or curing line.

This high temperature heat treat line extracts solvent from nonwoven substrates, using recovered heat from a thermal oxidizer as the sole heat source, featuring turret unwind and winders for continuous operation.

Get Quote

Membrane & Filtration

Pyradia is an experienced manufacturer of custom designed filtration membrane production line, for a variety of applications, such as water treatment membranes: Reverse osmosis (RO), Nanofiltration (NF), Ultrafiltration (UF), Microfiltration (MF), and various specialized filtration membranes. We design and build to your specifications all required modules, such as: knife box casting station, polymerization tanks, rinse tanks, dryers, laminators, unwinders, winders and web handling equipment. We developed a proprietary servo driven algorithms for extremely low tension control, allowing to process the most brittle and delicate unsupported membranes.

Get Quote

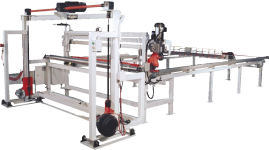

Calendring Lines

Pyradia is a renowned North American manufacturer of precision high pressure calendering lines, with up to 3000 PLI (525N/mm) compression capacity, available in both vertical and horizontal nip configuration, with roll skewing and roll bending active nip gap uniformity controls. Our proprietary servo-hydraulic positioning system allows for adjusting nip gap opening at full pressure and line speed, with position accuracy within few microns. Combine Pyradia calenders with a mass gauge for automatic closed loop web thickness control, available for a variety of substrates such as paper, film, nonwovens, graphite, fabric, foams, fiberglass, rubber and specialty materials.

To achieve the desired polymer properties, combine Pyradia calenders with Machine Direction Orientation (MDO), Traverse Direction Orientation (TDO or tenter frame), or coating and lamination stations. Pyradia calender rolls are thermal oil or electrical induction heated, with a large selection of compliant or hard surface finish.

Get Quote